by Garth Meyer

After the pandemic led to heightened national security concerns about U.S. reliance on foreign-made microchips, the federal government looked to ensure that we make more of our own. Northrop Grumman Space Park in Redondo Beach is part of this effort.

“Our micro-electronics (sites) are growing like crazy,” said Laura Chon, Northrop Grumman head of media relations, mission systems. “It’s critical now to bring those infrastructures back onshore.”

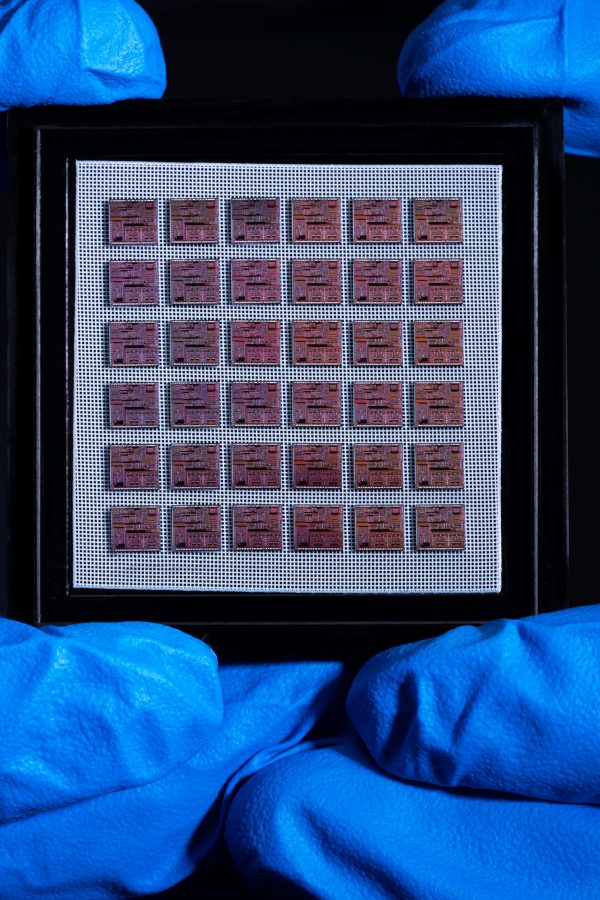

Not that Space Park ever sent them offshore, because most of its work is for defense contracts, thus the facility is part of increasing existing U.S. production. Northrop Grumman is now adding a hundred new employees (hires or transfers) to the Space Park microelectronics center, one of the company’s two chip foundries – the other is near Baltimore. A packaging facility operates in central Florida.

Expansion efforts at these three government accredited sites aim to quadruple Northrop Grumman’s chip production in the next five years.

“Our volumes (at Space Park) went up about 30% over last year,” said Ben Heying, Northrop Grumman’s local microelectronics foundry director since 2022. He leads the department that makes chips for both government and commercial use.

The business growth, as well as Northrop Grumman’s current chip volume is not related to the federal CHIPS and Science Act. The company is engaged with that national effort through regional technology hubs that would benefit the Department of War (recently renamed from “Department of Defense” by the Trump Administration).

Locals

The main chip made in Redondo Beach was invented here in 2012, the terahertz chip. It is 1,000 times faster than those in cell phones. Last year, it won the “Coolest Thing Made in California Award,” presented by the California Manufacturers & Technology Association.

“They are very, very good sensors,” Heying said.

In 2014, the terahertz – still made today at the Space Park foundry – set a World Record for fastest production microchip, a mark that remains standing.

The fastest in 2012 was 850 gigahertz. The terahertz is 150 billion cycles ahead of that.

“A cycle is essentially a wavelength,” Heying said. “The signal being transmitted. The cycle from the peak to the valley. It’s the speed of the wave.”

Space Park produces about a million chips per year; the work of 220 local employees, about half of whom work in manufacturing and the other half on the chips’ science and engineering.

“Ultimately, everyone is involved one way or another,” Heying said.

In this group are approximately 10 multi-generational duos – such as a father and son, mother and daughter.

The foundry is “very high-mix,” Heying said, split half and half between government and commercial work, as well as some in-house research and development.

Current Space Park customers – buying products or services – include Jet Propulsion Lab, for which Northrop Grumman makes climate science microelectronics and sensor technology; Lockheed Martin, which calls on Redondo Beach for low-noise amplifiers and defense systems’ advanced packaging; Nokia Bell Labs, for work on heterogeneous integration for “next-generation” consumer communication devices; and Rohde & Schwarz, foundry services for test and measurement equipment.

The terahertz chip is smaller than a grain of sand. They are used in government as well as commercial contracts.

“I can’t talk about the commercial ones; they are very sensitive,” Heying said.

Do you mean government?

“No, commercial.”

For these contracts, Space Park engineers work actively with their private sector counterparts in designing products; visiting their sites and vice versa.

Workers at the Redondo foundry also build satellites and other space applications, such as for the U.S. Space Development Agency’s Proliferated Warfighter Space Architecture Program – a network of military satellites. In August 2024, the U.S. Space Force launched two Northrop-Grumman built, Space Norway satellites for an Arctic broadband mission – to supply communications coverage over the Arctic.

What is the main difference between a government/military project and commercial?

“With a military contract, it’s as soon as possible, there’s that real need to go fast,” Heying said. “For the commercial, oftentimes the commercial is pushing us even faster, to full-on production.”

Another use of the chips is for the U.S. Department of War systems’ security imaging, high-speed secure communications and data collection.

Further government use for the chips is in civic satellites – NOAA, for example, amplifying atmospheric temperature signatures to predict long-term climate patterns.

Gallium Nitride

Heying has a Phd in material science and engineering from U.C. Santa Barbara. He began his career at TRW in 2001, before it was bought by Northrop Grumman, early in a research and development phase for the compound gallium nitride as a semiconductor (chip).

It is now one of the hundreds of different types of chips made at Space Park. Gallium nitride (GaN) chips can withstand space conditions better than standard silicon or other materials.

“GaN has many special properties that we can utilize. It is able to do things with much higher power than other semiconductors,” Heying said. “With GaN we could get six to 10 times more power out of a single chip than we could from more traditional semiconductors. We can send out a larger signal to direct things farther and farther away.”

The term “semiconductor” refers to a chip.

As an accredited U.S. Government “trusted foundry,” the 70-year-old Space Park operation has an added layer of security. It has access to more than 800 materials.

The site innovates through “critical collaborations,” said Mike Barsky, Northrop Grumman director of external sales, based in Redondo Beach. “The customers we serve demand timely, cost competitive and high-performance semiconductor solutions because their applications are among the most complex and critical to the infrastructure on Earth, and in outer space. Whether it’s in the skies, at sea, on land or in orbit, Northrop Grumman’s microelectronics need to perform with unmatched reliability.”

The company has long offered semiconductor fabrication, and other technologies to its customers, which Northrop Grumman now describes as “supporting the nation’s push for onshoring.”

During the pandemic, lack of U.S.-chip production showed across various industries, such as auto manufacturing, causing production delays while awaiting chips from overseas. Taiwan is one of these key suppliers. Chinese threats to their independence have made their supply capability less reliable.

“It’s an interesting capability we have here in the South Bay, and we’ve had it for a very long time,” Heying said. ER